Carbon Fiber Weaves: What they are and why to use them

May 20, 2023

Leave a message

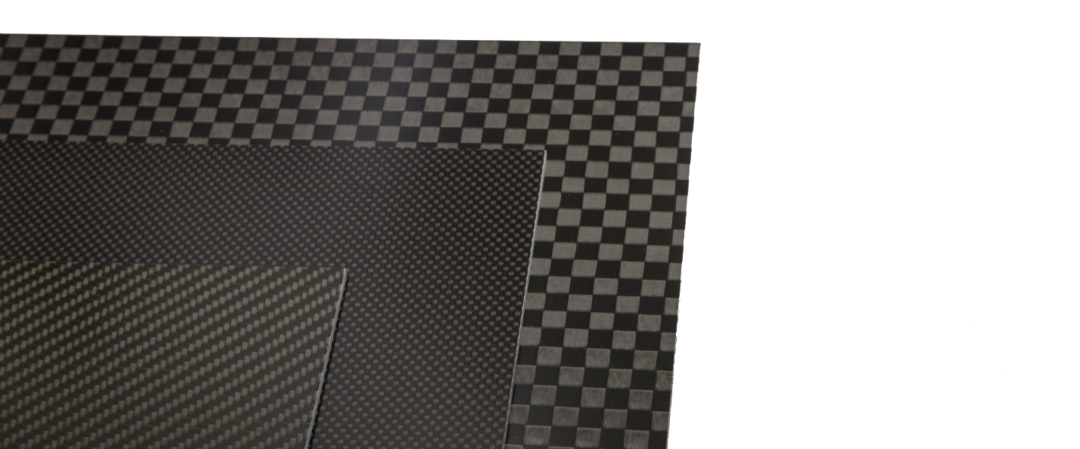

If you've ever wondered why one piece of carbon fiber might look different than another, you're not alone. Carbon fiber comes in many different weaves, each serving a different purpose, and it's not just decorative.

Carbon fibers are made from precursors such as polyacrylonitrile (PAN) and rayon. Precursor fibers are chemically treated, heated and stretched, then carbonized to create high-strength fibers. These fibers, or filaments, are then bundled together to form tows, which are identified by the number of carbon filaments they contain. Common towing classes are 3k, 6k, 12k and 15k. "k" means one thousand, so a 3k tow is made of 3,000 carbon filaments. A standard 3k tow is typically 0.125" wide, so packs a lot of fiber into a small space. A 6k tow has 6,000 carbon filaments, a 12k tow has 12,000 carbon filaments, and so on. Lots of high-strength fibers bundled together are what make carbon fiber such a strong material.

Woven carbon fiber

Carbon fiber usually comes in the form of a woven fabric, which makes it easier to work with and, depending on the application, can provide additional structural strength. As a result, carbon fiber fabrics come in many different weaves. The most common are solid, twill, and ribbon satin, and we'll look at each in more detail.

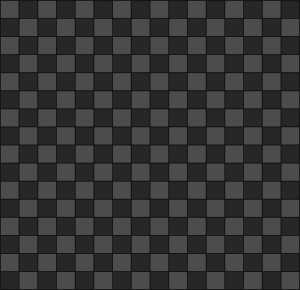

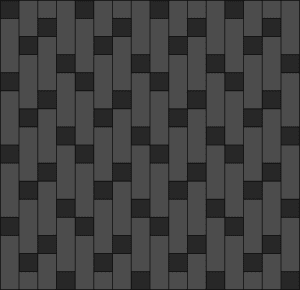

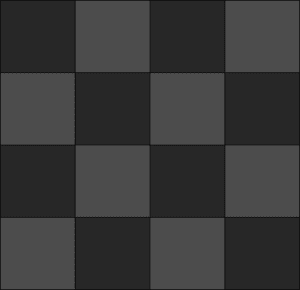

plain weave

The plain-weave carbon fiber panels appear symmetrical, with a small checkerboard appearance. In this weave, the tows are woven in an over/under pattern. The short spacing between the weaves gives the plain weave a high degree of stability. Fabric stability is the ability of a fabric to maintain its weave angle and fiber orientation. Due to this high level of stability, plain weave is less suitable for complex contoured layups, it will not be as flexible as some other weaves. Generally speaking, plain weave is suitable for flat sheets, pipes and two-dimensional curves.

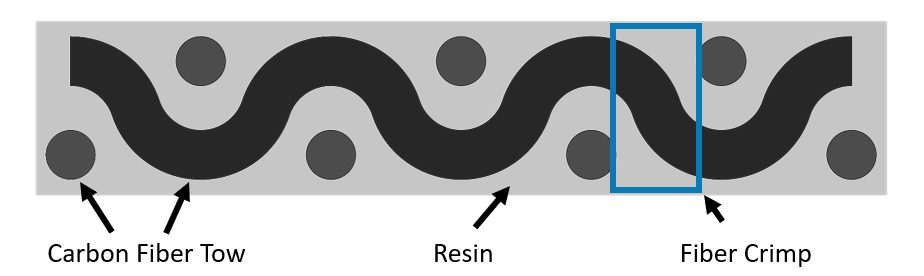

One disadvantage of this weave pattern is rough crimp (the angle the fibers make when weaving, see below) in the tow due to the short distance between interweaves. Rough crimps create stress concentrations that can weaken the part over time.

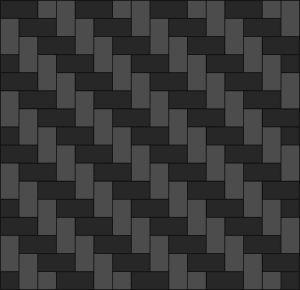

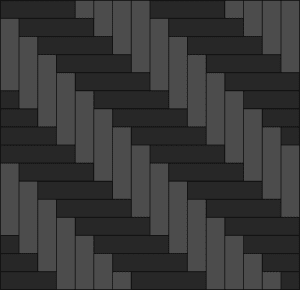

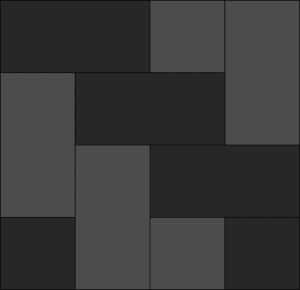

Twill weave

Twill acts as a bridge between the plain weave and the satin weave we'll discuss next. Twill is flexible enough to form complex contours and is better at maintaining fabric stability than saddle satin weave, but not as good as plain weave. If you follow a tow in twill, it goes through a certain number of tows and then through the same number of tows. The above/below pattern creates a diagonal arrowhead appearance known as a "diagonal line". The longer distance between tow interweaves means less crimping and less potential stress concentration compared to a plain weave.

2×2 Twill

4×4 Twill

2×2 Twill is probably the best known carbon fiber fabric in the industry. It is used in many cosmetic and decorative applications but is also highly functional, it has both moderate formability and moderate stability. As the name of the 2×2 implies, each tow will pass through 2 tows and then through 2 tows. Likewise, a 4×4 twill will go through 4 tows and then 4 tows. It is slightly more formable than 2×2 twill because the weave is not as tight, but it is also less stable.

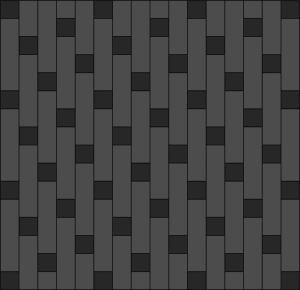

Harness Satin Weave

The satin weave was devised thousands of years ago to create silk fabrics that have excellent drape while looking smooth and seamless. For composites, this drapability means it can form and wrap complex contours with ease. Because of the high formability of this fabric, it is expected to have low stability. The common weaves are four-haddle (4HS), five-haddle (5HS) and eight-haddle (8HS). As the number of satin weaves increases, formability increases while fabric stability decreases.

4HS

5HS

8HS

The number in the Harness Satin name indicates the total number of tows passed. For 4HS it will be over 3 tows and then under 1 tow. For 5HS it will be over 4 tows then under 1 tow and for 8HS it will be over 7 tows then under 1 tow.

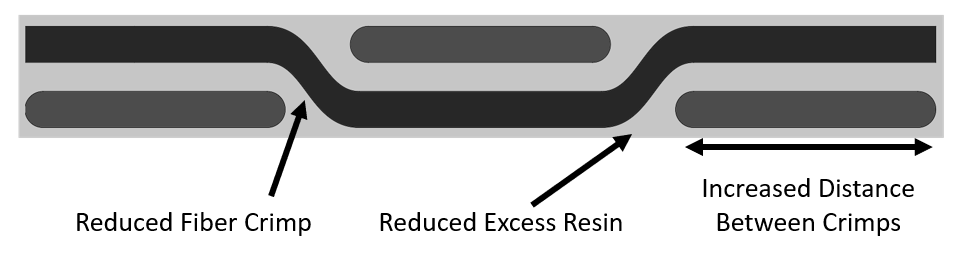

Spread Tow vs. Standard Tow

Spread tow materials can be a good compromise between using unidirectional materials and standard woven materials. When fiber tows are woven up and down to form a fabric, strength is reduced due to crimps in the tows. As you increase the number of filaments in a standard tow, say from 3k to 6k, the tow becomes larger (thicker) and the crimp angle becomes sharper. One way to avoid this is to spread the filaments into wider tows, known as spread tows, which has several benefits.

Spread tows provide a smaller crimp angle than standard tow braids and can reduce crossing defects by increasing smoothness. Lower crimp angles will result in higher strength. Spread tow materials are also easier to work with than unidirectional materials and still have fairly good fiber pull-up prevention.

Spread plain tow

Spread tow twill weave

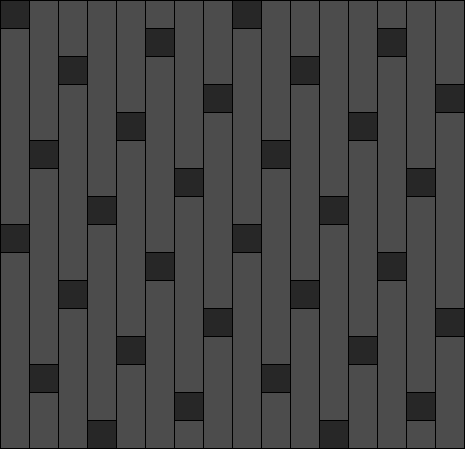

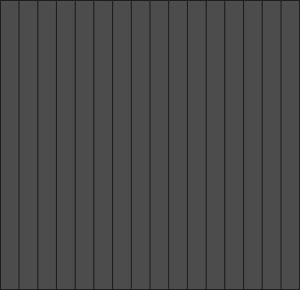

unidirectional

As the name suggests, uni means one, and all the fibers face the same direction. This provides some high strength advantages to unidirectional (UD) fabrics. UD fabric is not woven and does not have any crimped interwoven fibers that would weaken the structure. Instead, there are continuous fibers that add strength and stiffness. Another benefit is the ability to customize the stackup with greater control over performance characteristics. A bicycle frame is a great example of how UD fabrics can be used to tune performance. The frame needs to be stiff in the bottom bracket area to transfer the rider's power to the wheels, but it also needs to be compliant and flexible so as not to overwhelm the rider. With UD materials, you can choose the precise orientation of the fibers to achieve the desired strength.

A major disadvantage of UD is its maneuverability. UD falls apart easily during layup because it has no interlaced fibers to hold it together. If the fibers are placed incorrectly, it is nearly impossible to reorient them correctly again. Machined parts made from UD fabrics can also cause problems. If any fibers are pulled up where the feature was cut, those loose fibers will be pulled up all the way through the part. Typically, if a UD material is selected for layup, a layer of woven material is used for the first and last layers to improve processability and part durability. This is what hobbyist drone frames do all the way to production rocket parts.

Send Inquiry